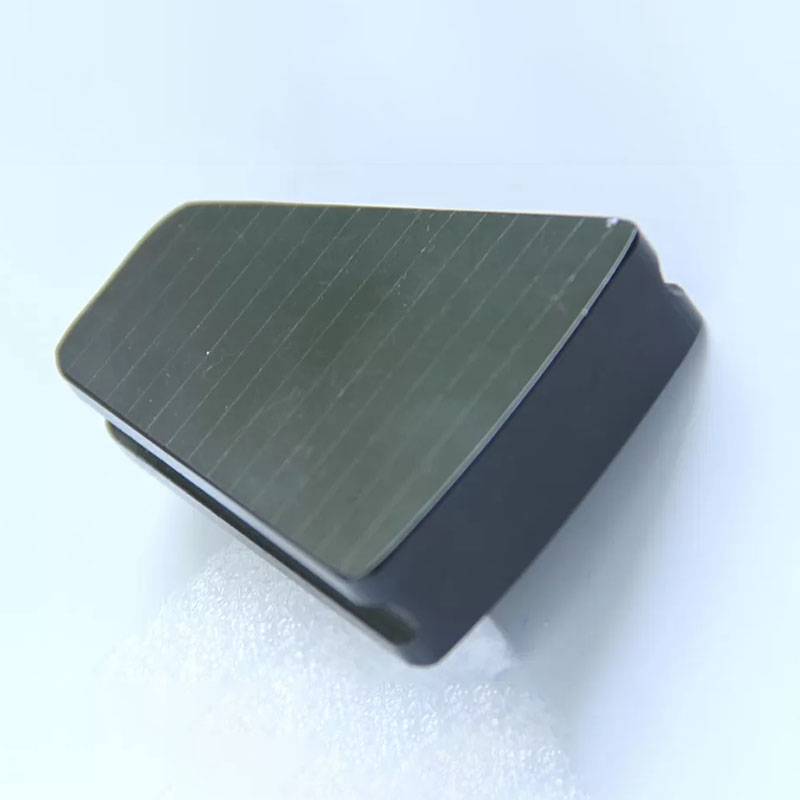

Samarium Cobalt Magnets, also known as SmCo magnets, are a type of rare-earth magnet made of an alloy of samarium and cobalt. They are known for their high resistance to demagnetization and excellent temperature stability, making them ideal for applications in harsh environments where other types of magnets may not perform as effectively.

Hangzhou Xinfeng Magnetic Materials Co., Ltd. has been at the forefront of SmCo magnet production, specializing in a wide range of magnetic materials including NdFeb magnets, Alnico magnets, Ceramic (Ferrite magnets), Rubber magnets, and Magnetic Assembly. With a strong focus on research and development, the company has been able to consistently improve the performance and reliability of their products.

"Our strong magnets are widely used in various industries including motor, electroacoustic, automotive, instrument, communication, and household applications," said a spokesperson for Hangzhou Xinfeng Magnetic Materials Co., Ltd. "We are committed to providing our customers with high-quality magnetic solutions that meet their specific requirements."

The China Samarium Cobalt Magnets produced by Hangzhou Xinfeng Magnetic Materials Co., Ltd. have been proven to deliver superior performance in a wide range of applications. Their high coercivity and energy product make them well-suited for use in electric motors, sensors, and magnetic couplings. Additionally, their ability to maintain their magnetism at high temperatures makes them an ideal choice for aerospace and automotive applications.

The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that their SmCo magnets meet the highest industry standards. With a focus on innovation and continuous improvement, they have been able to stay ahead of the competition and remain a trusted supplier of magnetic materials to customers around the world.

In recent years, the demand for high-performance magnetic materials has been on the rise, driven by technological advancements and the need for more efficient and reliable products. This has created new opportunities for companies like Hangzhou Xinfeng Magnetic Materials Co., Ltd. to expand their product offerings and capture a larger share of the market.

With a strong commitment to customer satisfaction and a dedication to excellence, Hangzhou Xinfeng Magnetic Materials Co., Ltd. is well-positioned to meet the growing demand for high-quality magnetic materials. Their China Samarium Cobalt Magnets, in particular, continue to gain recognition for their exceptional performance and reliability in a wide range of applications.

As the global market for magnetic materials continues to evolve, Hangzhou Xinfeng Magnetic Materials Co., Ltd. remains focused on delivering innovative solutions that address the unique needs of their customers. By investing in research and development and leveraging their extensive expertise in magnet technology, they are poised to maintain their leadership position in the industry.

In conclusion, the breakthrough in China Samarium Cobalt Magnets by Hangzhou Xinfeng Magnetic Materials Co., Ltd. represents a significant advancement in the field of magnetic materials. With their proven track record of delivering high-quality products and their commitment to continuous improvement, the company is well-equipped to meet the increasing demand for SmCo magnets in various industries. As technology continues to advance, the role of magnetic materials in powering a wide range of devices and equipment will only become more crucial, and companies like Hangzhou Xinfeng Magnetic Materials Co., Ltd. are at the forefront of driving these innovations.